|

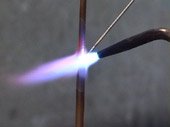

BRAZING

Brazing is very much like soldering since flux is applied to tightly fitted metal parts that are then heated to the point where filler material will melt and be drawn into the joint. silver soldering and hard soldering are terms incorectly used to refer to brazing. Brazing is different from soldering because it takes place at temperatures over 840 degrees F and below the melting point of the base metals. The metals are not fused, but held together by the filler metal adhering to the base metals through capillary action. There are a number of industrial brazing processes,such as dip brazing, furnace brazing, and induction brazing. The home welder is likely only to do torch brazing. Torch brazing can be done with an oxyfuel torch using acetylene as the fuel gas or ant other fuel gases. For brazing to work, the gap between the parts must be between 0,002 and 0.010 inches. If the gap is too big, the strength of the joint is lessened. Gaps between parts can be measured with a feeler tool, available at automotive stores. Items to be brazed must be clean and free from rust, corrosion, grease, oil and cleaning compound residues. Brazing is often used commercially to join dissimilar metals such as tungsten carbide saw teeth to a steel saw blade. Another common use for brazing is in lugged bicycle frames. Because nearly every metal can be joined using brazing, it is highly suitable for artists and art applications.

|